Ribs, Ribs Everywhere, and Not a Drop to Drink.

WE HAVE RIBS!

The second generation ribs are in and they are

very nice I must say. See pics below. These ribs are made from rigid

polyurethane foam, the same material I tried to cast ribs from. These are made

from 1” sheet foam routed to shape and capped with an aluminum capstrip top and

bottom. I had to make wood templates by hand from my CAD files so it took some

time since the last post. The cap strips are .020” aluminum bent into a “C”

channel and then hand fluted and fitted to each rib, then attached to the foam with contact cement, a time consuming process. The ribs are painted,

white in this case, with gloss exterior latex paint to protect them from UV damage.

This particular rib weighs 13oz, I haven’t weighed an original rib yet but they

“feel” about the same. I suspect it is slightly heavier with the paint. These

ribs are much stiffer than the original ribs and I have to say I am quite pleased with how they turned out.

Finished Rib

Foam Blank painted with acrylic latex paint

Upper Capstrip, formed to match upper surface contour

Lower capstrip

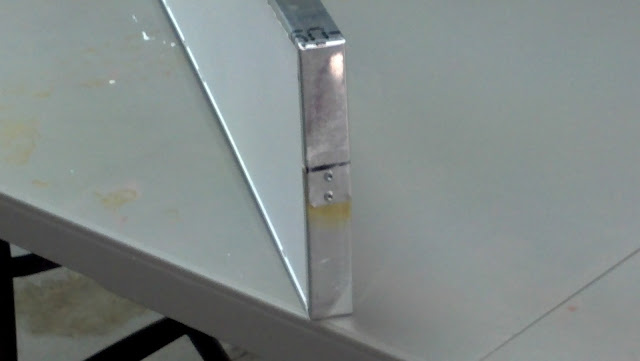

Upper and Lower Capstrips fastened with two stainless rivets

Closeup

Corner Detail

A youtube video documenting the rib making process is in the

works. Perhaps it will be of some help as part of a video construction manual.

I am currently making the sheet metal brackets that attach

the ribs to the spar and trailing edge. Complete wings are now within a foreseeable

future.

More Next Time,

Gene

Fltofancy@gmail.com