A Wise Man Can Hear Profit in the

Wind

Ferengi

Rules of Acquisition 22

Busy, Busy, Busy…….There is never enough time in the day.

Many progressive things have come to pass in the

few months since my last post. I have acquired a very nice Lazair Series III

from Michigan and have been working to get it in airworthy condition. In

addition to typical maintenance issues on this bird I have installed a set of

Black Max Brakes and it has much improved ground handling. Have a look at the

pics below to see the mods. If anyone is interested I have a complete kit

available to do the conversion. Therefore I now have two complete sets of

original Lazair wheels and brakes available for sale with nosewheels (rotating

skid). These first two pictures are before the brake mod, and after.The Black Max Wheels give the Old Girl a sporty look don't you think? The extra wide stance reduces side sway when taxiing too.

The brake mod has a small problem, with a very beneficial fix. The master cylinder shaft hits the forward fuselage tube and you lose about 1/2" of rudder pedal movement.

The fix is to add the rudder belcrank extension you see. This extension adds one inch to the rudder pedal throw, increases the total rudder deflection and "speeds up" the rudder pedal movement, i.e. more throw per degree of pedal travel. This is beneficial because the Lazair were always wanting for more rudder authority.

Here are some development pictures of the brake install.

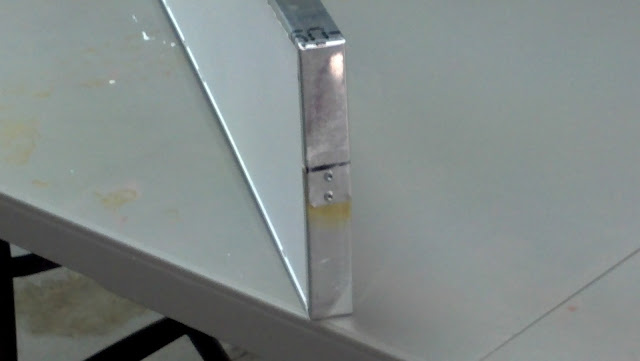

And some photos of the Axle and Caliper installation.

The last pics show the pedal mods needed to get enough throw on the master cylinders. I installed a toe tube on the pedal to give more throw and to widen the brake pedal, I always thought they were too narrow.

In addition to gaining an extra bird I have been progressing on the Mark IV. I have installed the endcaps on the ailerons, sorry no pics right now. Also I have built a test stand to run-in the Evolution Radials and have run the first one. You can see a poor quality video here: http://youtu.be/KpmPpXnu5cE. I took this video from my cell phone so it’s not the best but you get a good look at my test stand and hear the engine run. These are real hoss’s for powerplants and are really going to liven up the Mark IV. I have a 32 x 12 Valley View break-in prop on right now and this engine spins the devil out of that thing. I will need to make an external electric starter as hand propping this beast is both dangerous and tiring. Maybe a converted marine outboard starter motor? Taking suggestions on this one.

More Next Time,

Gene

Fltofancy@gmail.com